PUF Sheets

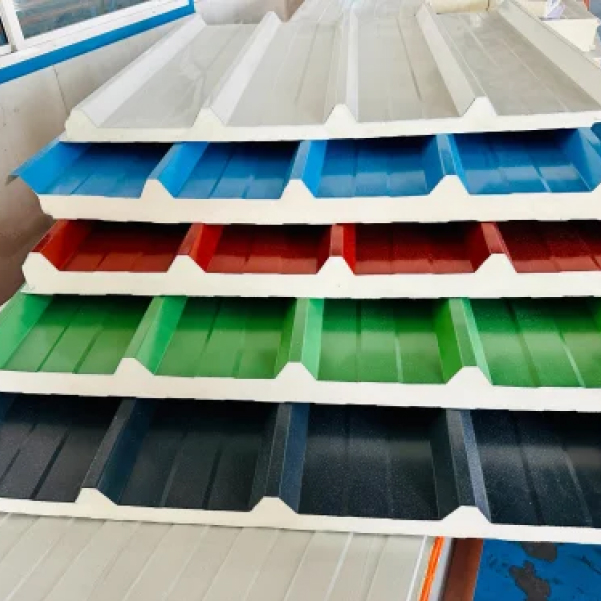

Leading manufacturer of puf panel: wall puf panel, roof puf panel, insulated puf roof panel, puf panel for farm house and puf panel for shelter offices and more.

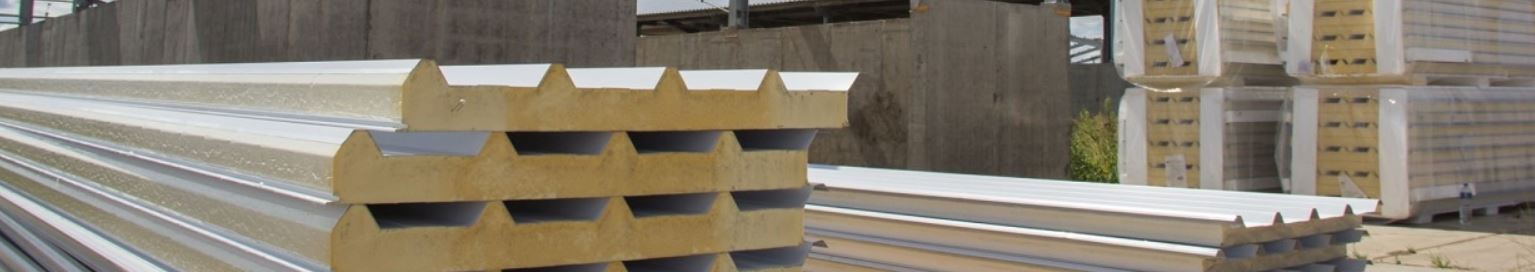

We are pleased to introduce ourselves as one o f the leading manufacturer and supplier of optimum quality PUF Insulated Panels for Cold rooms and Clean rooms, Porta Cabins, Containers, Prefabricated Shelters, Vehicle Body Building. Based in Hyderabad, India our company is able to deliver high quality products at excellent price. With years of experience, expertise and skill our company has given shape to many extraordinary products.

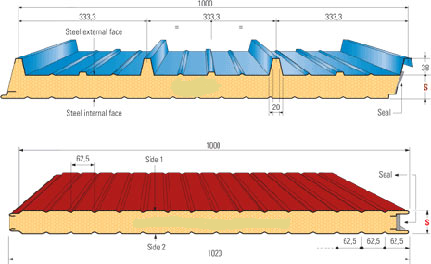

Our product range is designed according to the specifications of the customers keeping in mind the required standards and the latest trends. Our company is supported with high technology manufacturing unit with advanced machines and tools. The entire products are easily transportable and can be installed at any site. Panels and Prefabricated structures offered by us are capable of withstanding extreme weather conditions and some of them are used widely in seismic zones.

Our wide varierty of PUF insulated panels for various type of applications:

Installation Process of PUF Sheet for Roofing and Wall Panels

The installation process of for roofing and wall panels requires careful planning and adherence to industry best practices. Here is a general overview of the installation process:

- Surface Preparation: Ensure that the roof or wall surface is clean, dry, and free from any debris or contaminants. This provides a suitable base for the installation.

- Measurements and Cutting: Take accurate measurements of the roof or wall area to determine the required size of the panels. Use appropriate tools to cut the panels to the desired dimensions.

- Fixing and Fastening: Secure the panels to the roof or wall using suitable fasteners. Follow the manufacturer’s guidelines and recommendations for the correct type and spacing of fasteners.

- Sealing and Waterproofing: Apply sealants and waterproofing materials to the joints and seams of the sheet. This helps to prevent water leakage and ensures the overall integrity of the installation.

- Finishing and Trim Work: Complete the installation by adding finishing touches, such as edge trims and flashing, to provide a neat and professional appearance. Ensure that all trim work is securely attached and properly sealed.